Description

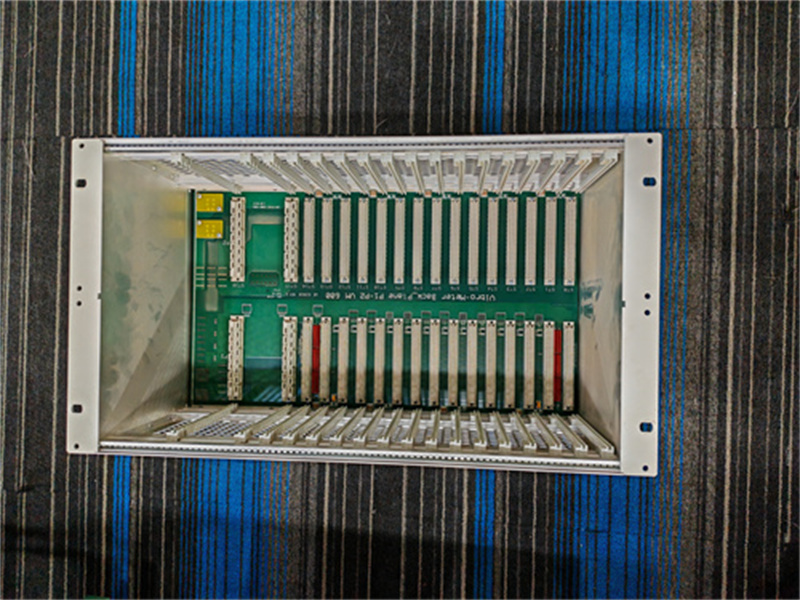

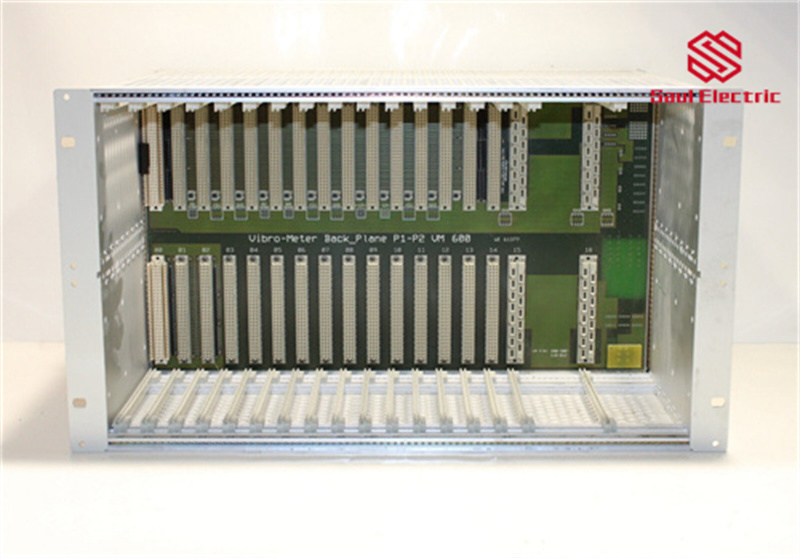

The VM600 204-040-100-012 is a VIBRO-METER vibration monitoring system with the following features:

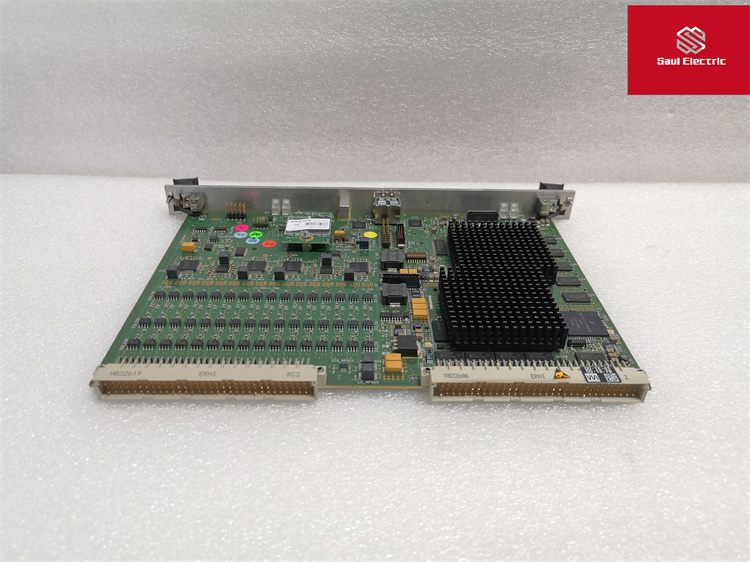

Intelligent Motion Transform: The system utilizes intelligent motion transform and an efficient tool management system, as well as 80-bit floating point nanometer accuracy, to analyze sensor drift and verify transmitter operation, ensuring accurate measurement and analysis.

Advanced control capabilities: With advanced control capabilities previously reserved only for advanced CNC control segments, the VM600-204-040-100-012 can benefit from a range of performance features.

Global applicability: The ability to use a variety of CNC programming methods used around the world provides machine manufacturers with the opportunity to select a single CNC device for their products to be sold on the global market.

Graphical work step programming system: Using the graphical work step programming system of stores and stores, the programming time of small production can be further reduced.

Modular design: The modular design can be flexibly integrated into various application systems.

High precision and reliability: The system uses high-precision sensors and advanced signal processing technology to achieve high-precision vibration monitoring, and uses a rugged design and rigorous test procedures to ensure stable operation of products in harsh environments.

High flexibility: Supports a variety of communication protocols and can be flexibly integrated into various application systems.

Easy to use: provides a friendly user interface and powerful programming functions for easy user operation and programming.

Functional perfection: Support a variety of vibration monitoring functions and data analysis functions to meet different application requirements.

Real-time monitoring: The main function of the system is to monitor the operating status and parameters of mechanical equipment in real time, such as temperature, pressure, speed, vibration, etc.

The VM600 204-040-100-012 vibration monitoring system is suitable for a variety of industrial applications, and it is an important choice to consider, whether for machine manufacturers or system integrators.

| IOC 8T 200-580-000-111 |

| IOC8T200-580-000-111 |

| IOC4T 200-560-000-111 |

| VM600 IOC4T |

| VM600 MPC4 |

| VM600 XIO16T |

| VM600 IOCN |

| VM600 CPUM |

| VM600 RLC16 |

| VM600 RPS6U |

| VM600 19″ 6U |

| 244-704-000-042 |

| 200-582-600-013 |

| 200-560-000-111 |

| 200-510-071-113 |

| MPC4 200-510-076-115 |

| MPC4 200-510-SSS-1Hh |

| VEGAWAVE61 |

| VM600 IOC4T |

| VM600 MPC4 |

| EA402 913-402-000-012 |

| GSI127 244-127-000-017 |

| RPS6U |

| IQS450 204-450-000-002 |

| Galvanic separation unit GSI124 |

| MPC4 200-510-SSS-1HH |

| RPS6U 200-582-500-12x |

| IOCN 200-566-000-1Hh |

| VM600 MPC4 200-510-017-017 |

| VM600 MPC4 200-510-070-113 |

Reviews

There are no reviews yet.